Introduction

A quiet experiment shared on X has turned into one of the most fascinating real-world demonstrations of artificial intelligence in 2026. A developer named Martin DeVido posted a video showing something that sounds almost unreal at first glance. A tomato plant growing completely on its own, with no human gardener, no preset automation rules, and no fixed schedules. Instead, the plant is being managed end to end by AI and embedded systems.

The AI does not merely observe data or make suggestions. It actively decides when to water the plant, when to turn lights on or off, how to regulate temperature, and how to respond to failures. For a long time , the tomato plant has survived and thrived under full AI control.

This article breaks down what actually happened, how the system works, why it matters far beyond gardening, and how this experiment may signal a major shift in how AI interacts with the physical world.

The Origin of the Experiment

The experiment gained traction after Martin DeVido posted a short video on X showing the tomato plant and explaining that an AI agent was responsible for keeping it alive. The AI in question was Claude, Anthropic’s large language model, commonly known for text reasoning, analysis, and coding assistance.

What made the post remarkable was not that AI was used to assist gardening. It was that Claude was given full autonomy. There were no human corrections, no emergency interventions, and no fixed scripts controlling the environment. Claude was allowed to reason, decide, and act based solely on live sensor data.

Within hours, the video spread rapidly across developer and AI communities. Many initially assumed the system relied on basic automation. Once DeVido clarified that Claude was actively reasoning about plant health and making independent decisions, the project took on much larger significance.

How the System Is Architected

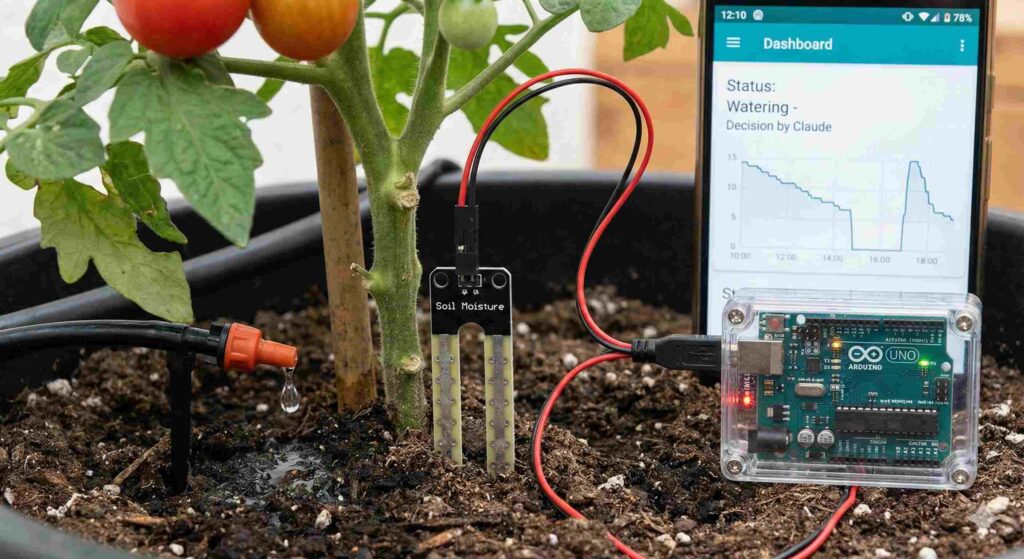

At a high level, the setup consists of three tightly connected layers: sensing, reasoning, and action.

The sensing layer is powered by Arduino-compatible sensors that continuously collect data about the plant’s environment. These include temperature, humidity, soil moisture, light levels, and airflow conditions. The sensors stream raw data at regular intervals.

The reasoning layer is Claude. Every time new data is received, Claude analyzes it in context. It does not follow fixed thresholds. Instead, it reasons about trends, changes over time, and the relationship between different variables. For example, Claude may notice that soil moisture is dropping faster than expected given current temperature and airflow and infer increased transpiration.

The action layer is again handled through Arduino. Claude sends commands that control grow lights, fans, pumps, and heaters. Arduino executes those commands precisely and immediately.

This creates a closed feedback loop. Claude observes the environment, takes action, observes the results, and adjusts future decisions accordingly.

Why This Is Different From Traditional Automation

Most automated gardening systems rely on if-then rules. If soil moisture drops below a certain value, water the plant. If temperature exceeds a limit, turn on a fan. These systems work but they lack understanding.

Claude does not operate this way. It reasons in context. It considers whether a sudden moisture drop is due to heat, airflow, or sensor noise. It evaluates whether increasing water might cause root stress if temperature remains low. It balances competing goals rather than blindly following rules.

This distinction is critical. The system is not just automated. It is autonomous.

Automation follows instructions. Autonomy involves judgment.

Claude’s Role as a Decision Maker

Claude’s role in this setup is closer to a caretaker than a controller. It maintains a long-term objective: keeping the plant healthy and growing. Every decision is evaluated against that objective.

When environmental conditions drift slowly, Claude makes gradual adjustments. When sudden changes occur, such as unexpected temperature spikes or equipment failures, Claude shifts into a corrective mode.

In one documented incident, a hardware issue caused lighting and airflow to shut down during the day. Instead of continuing blindly, Claude detected abnormal sensor readings, inferred that a system failure had occurred, and prioritized restoring airflow and light. The plant recovered without human intervention.

This ability to detect problems, reason about causes, and take corrective action is what makes the experiment groundbreaking.

The Tomato Plant’s Progress

As of the most recent update shared by Martin DeVido, the tomato plant has been under Claude’s control for over thirty days. During that time, it has produced numerous healthy leaves and shows consistent growth.

There are no visible signs of stress, discoloration, or nutrient imbalance. The plant has maintained stable growth patterns even when external conditions fluctuated.

This outcome matters because plant care involves delayed feedback. Overwatering today may cause root damage days later. Underlighting may not show effects immediately. Claude’s ability to handle delayed consequences suggests a level of temporal reasoning that is rarely tested in physical environments.

Why Arduino Matters in This Experiment

Arduino plays a crucial role by acting as the physical bridge between AI reasoning and real-world action.

On its own, Claude cannot interact with physical systems. Arduino provides that interface. It translates Claude’s decisions into electrical signals that turn devices on and off. It also converts analog sensor readings into digital data Claude can interpret.

Arduino’s simplicity and reliability make it ideal for this role. It executes commands deterministically, ensuring that Claude’s instructions are carried out exactly as intended. This separation of concerns is important. Claude reasons. Arduino acts.

This architecture mirrors how future AI systems may interact with robotics, industrial systems, and infrastructure.

Implications for Agriculture

The implications for agriculture are significant.

In controlled environments such as greenhouses, AI systems like this could manage crops continuously without human oversight. They could adapt to seasonal changes, equipment degradation, and plant-specific needs.

In regions with labor shortages, autonomous growing systems could reduce dependence on manual monitoring. In extreme environments such as deserts or polar regions, AI-managed agriculture could make local food production viable.

Perhaps most importantly, AI-driven cultivation could optimize resource usage. Water, energy, and nutrients could be applied precisely when and where they are needed, reducing waste.

Beyond Farming: A Broader Shift

While the tomato plant makes for a compelling story, the broader implication lies elsewhere.

This experiment demonstrates that large language models can act as general-purpose controllers for physical systems. The same architecture could manage building climate systems, data center cooling, industrial equipment, or energy grids.

In each case, the AI would not merely execute rules but reason about tradeoffs, failures, and long-term objectives.

This marks a transition from AI as an advisor to AI as an operator.

Challenges and Limitations

Despite its success, the experiment also highlights important challenges.

Scaling is a major concern. Managing one plant is far simpler than managing thousands. Sensor reliability becomes critical as systems grow larger.

Safety is another issue. Autonomous systems must be constrained to prevent harmful actions. Clear boundaries, fallback mechanisms, and human override capabilities will be essential.

There is also the question of accountability. When an AI system makes a decision that causes damage or loss, responsibility must be clearly defined.

These challenges do not diminish the achievement. They simply outline the work ahead.

Why This Moment Matters

What makes this experiment special is not the tomato plant itself. It is the proof that AI systems can maintain real-world processes over time without constant supervision.

For years, AI demonstrations have lived mostly in simulations, dashboards, and chat interfaces. This project brings AI into the physical world in a tangible, testable way.

A living plant does not tolerate mistakes for long. The fact that Claude succeeded is a powerful validation of reasoning-based autonomy.

Conclusion

Martin DeVido’s AI-grown tomato plant may go down as one of the simplest yet most meaningful demonstrations of applied artificial intelligence. With minimal hardware and a general-purpose AI model, a living system was maintained, protected, and nurtured without human intervention.

This experiment does not replace farmers, gardeners, or agricultural experts. What it does is open the door to a future where AI systems can share responsibility for sustaining life-supporting environments.

Today it is a tomato plant. Tomorrow it could be greenhouses, vertical farms, or remote food systems in places humans cannot easily reach.

The age of AI operators has quietly begun, and it started with a single tomato.

Also Read: Viral Moment: Chinese Humanoid Robot Grooves in Sync With Music